Design, Engineering & Quality

Caliber prides itself in Design and Innovative solutions in the market place. At any stage of your products development we will be there to provide assistance and get your product to the market. We are a team of problem solvers that strive to find optimal design features and part performance.

Product Development Pipeline:

- Concept Feasability : How your design can be produced and how it functions as a consumer product.

- Alpha Research : Design Improvement with prototypes, design iterations and product feature changes.

- Beta Development : Completion of single cavity tooling production parts for testing & validation.

- Qualifications : Production Tooling and First Article completion.

- Product Launch : Stock level builds and Introduction to the market.

Caliber’s Product Development assistance encompasses Design, Engineering and manufacturing to speed your time to market. Success is achieved through cross functional team efforts with a “continuous improvement” mindset. Products are developed with specific “Value to the Customer” goals in mind. All components and assemblies are intimately examined and developed for ergonomics, fit and function, tolerance stacking, lifecycle performance.

Cost is the Driver:

The single most important benefit when working with us is that you will have a good idea of what capital and part cost will be for your component. Our business strives on getting you into a low cost production tool while minimizing cycle time with consideration of performance and cosmetics. We are very upfront with our costs so you can contribute to the optimized design. We are very forward about how your part will be priced based on a few simple parameters.

( Plastic Volume X Plastic Cost ) + Cycle Time = PART COST

Caliber recognizes the importance of Plastic cost is broken down into– commodity thermoplastics and Engineered Thermoplastics. Engineered Thermoplastics are very specific designed for superior product performance and can cost more but will also allow for optimized wall thickness and mass reduction. The size of your part can then be optimized to a level that can be molded in a shorter cycle time.

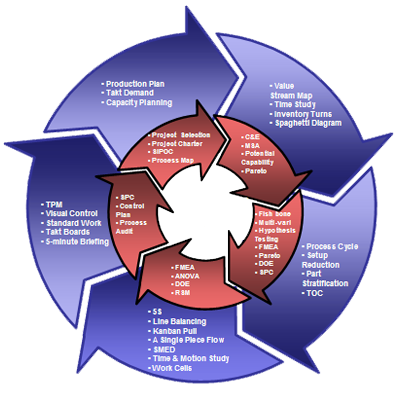

Six Sigma Development Methodology:

Caliber OEM takes your part quality very seriously and employs a tried and true Six Sigma development and qualification process. Prints are strategically developed with reference dimensions, standard dimensions and critical dimensions. We intimately work with you to understand critical areas of your parts and employ tolerance and tolerance stacking to achieve optimal components application lifecycle success.

“Hit the Target with the employment of robust processes”

Our First Article inspection process:

– Achieve all critical data points to a 1.33 Cpk (30 data points minimum)

– Achieve not critical data points to a 1.0 Cpk. (5 data points minimum)

– 3 rounds of this inspection required with separate operators and tool set-up.

Along with component first article qualification, Caliber also assists in product development with in- depth tools including: FMEA, FEA, DOE, Gage R&R, etc.